Plant operators always focus on how these jobs can be managed efficiently and with minimum impact on the environment for the least possible cost. The same applies to the treatment of industrial fluids such as mineral oils, cooling lubricants and wash liquids. Here, the aim is to increase the service life of these fluids, reduce wear on tools, prepare workpieces for further finishing and thus relieve strain on budgets by reducing the need for resources and avoiding waste materials.

Treatment of industrial fluids

- Treatment of metalworking coolants and wash liquids

- Cleaning and dewatering of lube oil, hydraulic oil and diesel oil

- Treatment of waste oil, used emulsion, MARPOL oil and oily water

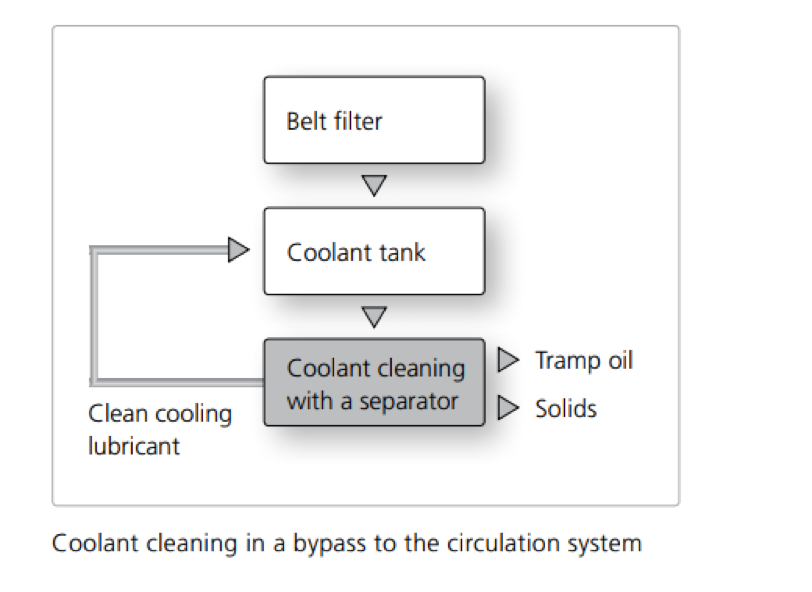

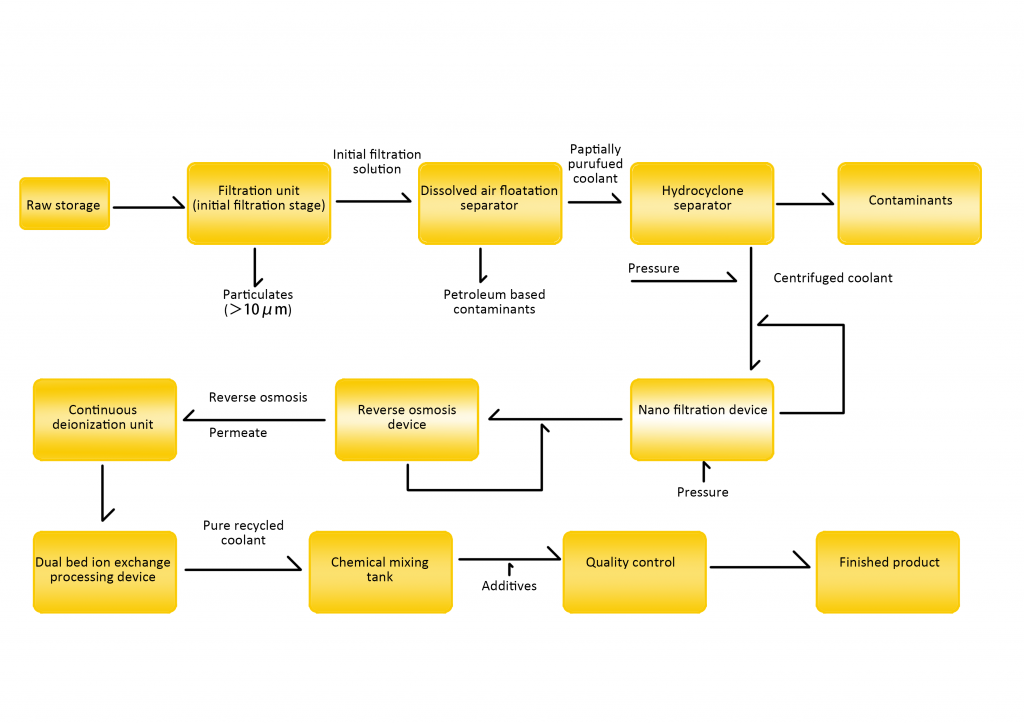

Cooling lubricants must regularly be rid of solid contaminants and tramp oil to maintain their properties. The earlier and more reliably this is done, the more consistently unplanned machine shutdowns and unhygienic production conditions can be avoided. The separators can be directly integrated in production to ensure smooth processing by means of early partial stream purification. The finest solids and tramp oil are separated off in one single step, thus achieving a four- to fivefold increase in the service life of the cooling lubricants used. Machine downtimes are reduced to a minimum. The product conditions are hygienic, and the reduction of the liquid volumes to be disposed of additionally improves the economic balance. Remove tramp oil reliably from wash liquids Separators also have an optimum effect in the treatment of industrial wash liquids. To maintain the optimum cleaning effect and ensure continuity of production, entrained particles and tramp oils must be separated out early. Separators separate these undesired constituents in the course of the production process. The treatment system convinces by its constantly high cleaning efficiency and a substantially reduced washing lye consumption. The service life of the washing liquid is significantly increased. Tool wear is reduced at the same time, whilst the quality of the machined work pieces increases.

Industrial Fluids Sample Processing Line