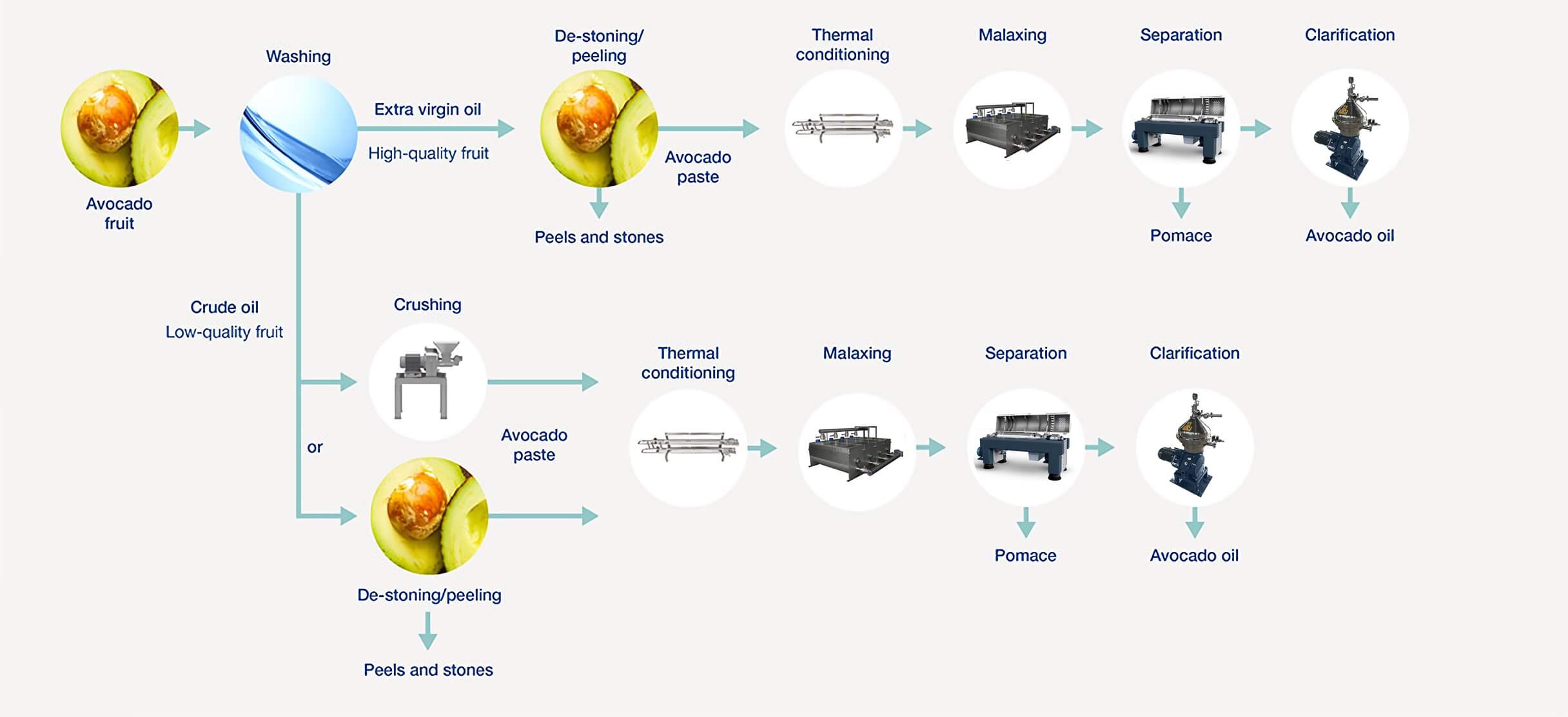

Avocado oil produce technique

After avocados are sun-ripened on the tree, they are hand-picked, sorted, washed, and then passed through pit and skin removers. Once the fruit is free of its skin and pit, it is malaxed at a low temperature to begin the oil separation process. The malaxers are constantly monitored for temperature and to reduce oxidation, the fruit is only malaxed for the minimal time necessary to make extra virgin avocado oil. After malaxing, the fruit is passed through a two-part centrifuge system that separates the pulp and water from the oil. Finally, a polishing separator fines out any remaining particulates to create our smooth, emerald green extra virgin oil that is truly unique.

Equipment for Avocado oil processing line

Belt fruit elevator

Transport raw material/avocado fruit to the pre-cooker.

Capacity: 1 t/H, Motor power: 0.75 kw, Material: Main body 304 stainless steel, Food grade plastic belt conveyor, with lifting hopper,Dimension (L*W*H): 3000*500*2000 mm

Bubble fruit washing & lifting machine

Washing avocado meat under the combined operation of air bubble, surfing, hoisting and spraying. Forced gas-boiling cleaning with low-level lifting

Capacity: 1 t/H, Material: 304 stainless steel, Dimension(L*W*H): 3800*1200*1650

Brush cleaning machine

Brush with spray head for avocado fruit cleaning.

Capacity: 1 t/H, Material: Main body 304 stainless steel, Dimension (L*W*H): 2500*800*1700 mm

Chain plate pre-cooker

By screw feeding, steam by side to preheat and soften fruit.

Capacity: 1 t/H, Motor power: conveyor 1.1 kw+ fan 2.2 kw +heater 2.0 kw, Material: 304 stainlsess steel, Dimension: 5500*800*1500 mm

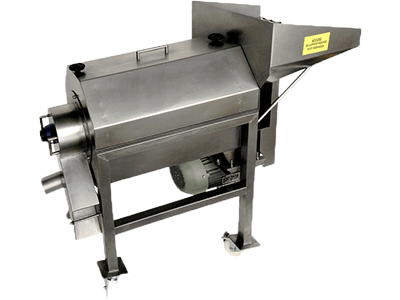

Fruit destoner

Auto de-stoned, High efficiency, without waste

Capacity: 1 t/H, Material: main body SUS 304, Motor power: 4 kw, Sieve: 14 mm, as per custom mode

Colloid mill

To mill meat into pulp.

Capacity: 1.0 t/H, Motor power:11 kw, Material: SUS 304

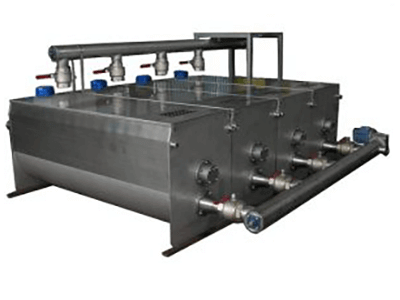

Curing equipment/Malaxer

By screw to max blending the liquid Heating by steam

Volume: 500 L , Power: 7.5 kw, Material: SUS 304, Dimension: 2670*800*1300 mm

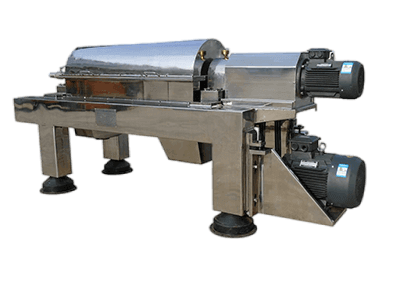

Decanter centrifuge

Decanter Centrifuges are popular solid-and-liquid separators used in multiple industries for a wide array of products. Decanters are used for the extraction of liquids from large proportions of solids. It makes use of medium-low speed suspension to process larger capacities of solids as compared to a Basket Centrifuge.

Disc stack centrifuge

Disc Stack Centrifuge is a high-speed, mechanical centrifuge used for the separation and purification of mixtures comprising of solids and liquids.

These machines can be used in a wide range of applications. For example, it can be used in extracting procedures for oil, for basic oil and water separation, and for filtration or the removal of impurities of any solid or liquid product.

Tubular Separator (Oil industrial model)

Tubular Separator is Crown Machinery’s most popular product to date. The company has been continuously improving its design for about 30 years already.

It is a high-speed centrifuge used in a variety of biological processes: from cellular harvesting up to the separation and purification of chemicals, food, blood, and even medicine.

Centrifugal pump

Pumping the fluid to tank, which is capable to adjust the flow rate from 1 ~ 400 M³/h.

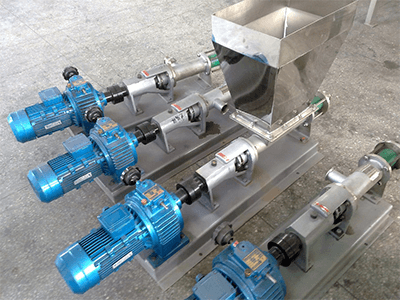

Screw Pump

Pumping the fluid to tank, which is capable to adjust the flow rate from 1 ~ 400 M³/h.

Holding tank

Storage the final Virgin Avocado oil product.

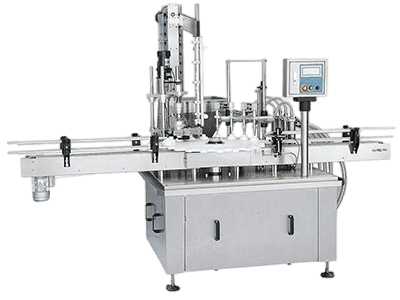

Filling machine

Customized filling machine equipment according to customer requirements,Check link : crown-machinery.net/packaging-machine