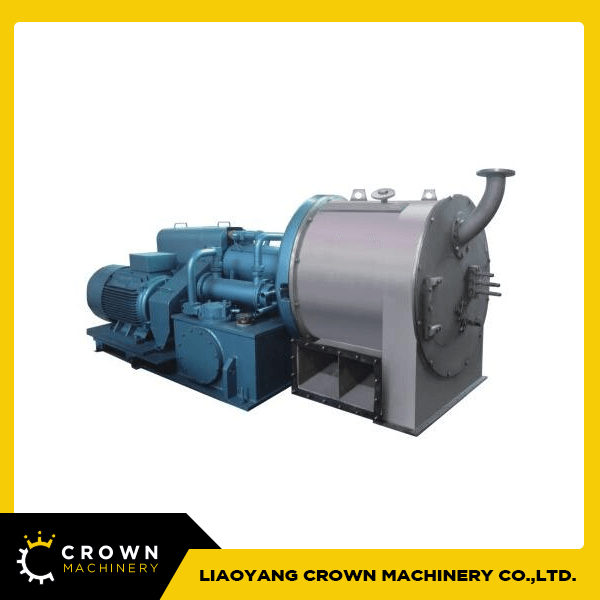

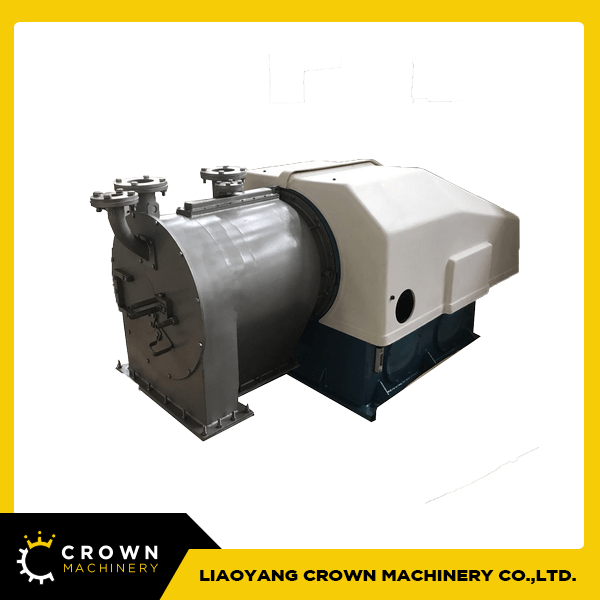

Crown Machinery™ Pusher Centrifuges

A pusher centrifuge is a type of filtration technique that offers continuous operation to de-water and wash materials such as relatively in-compressible feed solids, free-draining crystalline, polymers and fibrous substances.

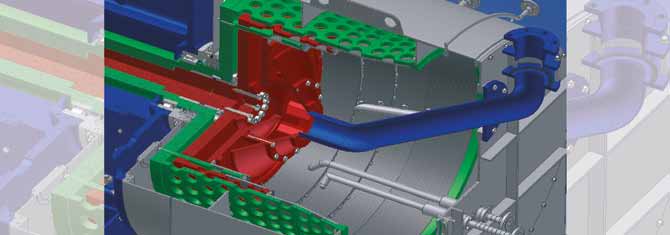

It consists of a constant speed rotor and is fixed to one of several baskets. This assembly is applied with centrifugal force that is generated mechanically for smaller units and hydraulically for larger units to enable separation.

The advantages of Pusher Centrifuges

Higher processing capacities

Best washing characteristics

Gentle handling

Description of our Pusher Centrifuges

A suspension feed enters the process to undergo pre-acceleration and distribution. The subsequent processes involve main filtration and intermediate de-watering, after which the main filtrate is collected. Wash liquid enters the washing step and final de-watering follows. Wash filtrate is extracted from these two stages. The final step involves discharge of solids which are then collected as the finished product. These process steps take place simultaneously in different parts of the centrifuge.

Pusher centrifuges are mainly used in chemical, pharmaceutical, food (mainly to produce sodium chloride as common salt) and mineral industries.

It is widely accepted due to its ease of modification, such as gas-tight and explosion protection configurations.

STL Series

STL Series is suitable for separating the suspension with solid particle size of more than 0.05mm and with the concentration of over 40%. It was widely used in chemical industry industry, fertilizer, manufacturing salt and alkali, especially suitable for the solid-liquid separation of ammonium bicarbonate, ammonium chloride, mirabilite, ammonium bicarbonate, sodium sulfate etc.

Two-Stage Pusher Centrifuge Specifications

| Model | STL400 | STL500 | STL630 | STL800 | STL1000 | |

|---|---|---|---|---|---|---|

| Basket | Diameter (mm) | 337/400 |

438/500 |

560/630 | 720/800 | 920/1000 |

| Lengh of Filtering area (mm) | 145/155 |

180/180 |

240/240 | 240/320 | 240/320 | |

| Speed (r/min) | 500-2200 |

1200-2000 |

1000-1800 | 800-1600 | 650-1250 | |

| Separating Factor | 503-1083 |

402-1120 |

350-1142 | 286-1145 | 236-875 | |

| Length of Pusher (mm) | 50 | 50 | 50 | |||

| Frequency Of Pusher (L/min) | 30-80 |

30-80 |

30-80 | 30-80 | 20-70 | |

| Main Motor Power (KW) | 11 |

30-45 |

37-55 | 55-75 | 75-90 | |

| Oil Pump Motor Power (KW) | 4 |

15 |

30 | 37 | 45 | |

| Production Capacity (t/h) | 1-8 |

5-15 |

8-25 | 15-40 | 18-50 | |

| External dimensions LxWxH (mm) | 2460*1286*1030 |

2750*1480*1290 |

3690*1600*1265 | 3700*1800*1450 | 4200*1900*1900 | |

| Gross Weight (Kg) | 2480 |

3100 |

4100 | 7000 | 12000 | |

Typical Industry Applications

Pharmaceutical

Organic intermediates

- Paraxylene,

- Adipic acid,

- Oxalic acid caprolactam,

- Nitrocellulose,

- Carboxymethylcellulose.

FOOD INDUSTRY

- monosodium glutamate,

- salt,

- lysine and saccharin.

PLASTIC INDUSTRY

- PVC

- Polyethyleneand polypropylene

- Resins

OTHER

- Peel cotton testa