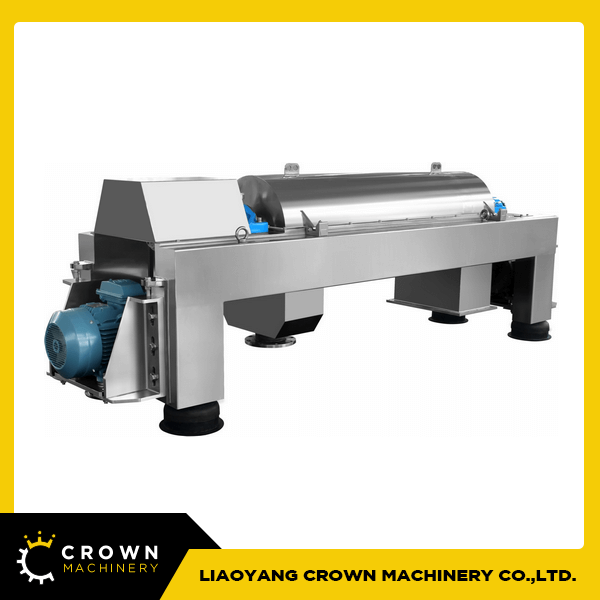

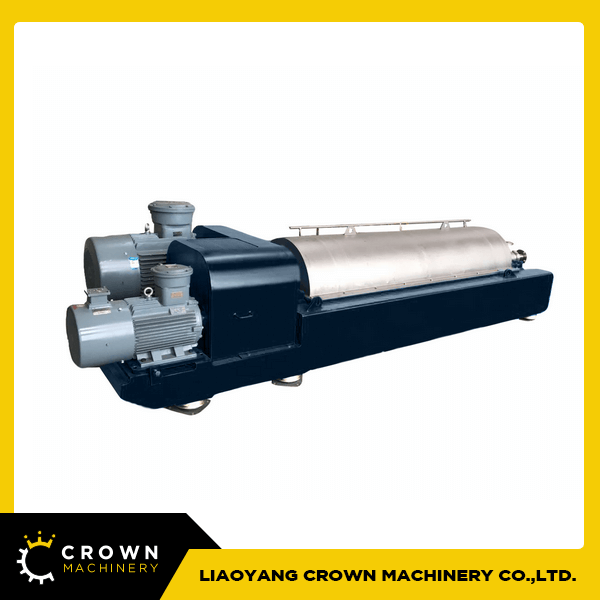

Crown Machinery™ Sewage Decanter

The decanter centrifuge apply for clarfy, dehydrate and classify, the suspensiens with 0.002~3 mm solid particles be filtrated. As structure fetures, the model of As structure fetures, the two pahse model of decanter centrifuge is suitable for separation and dehydration of industrial and domestic sewage.

Decanter Centrifuges for Sewage Treatment

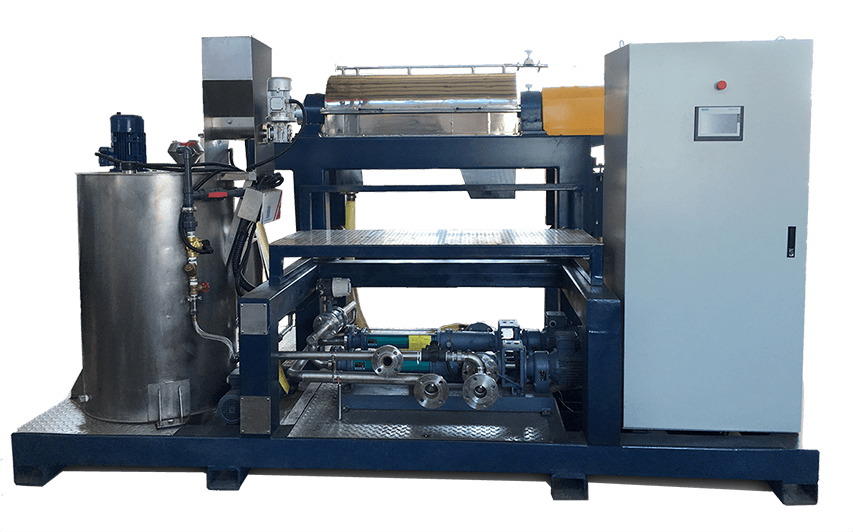

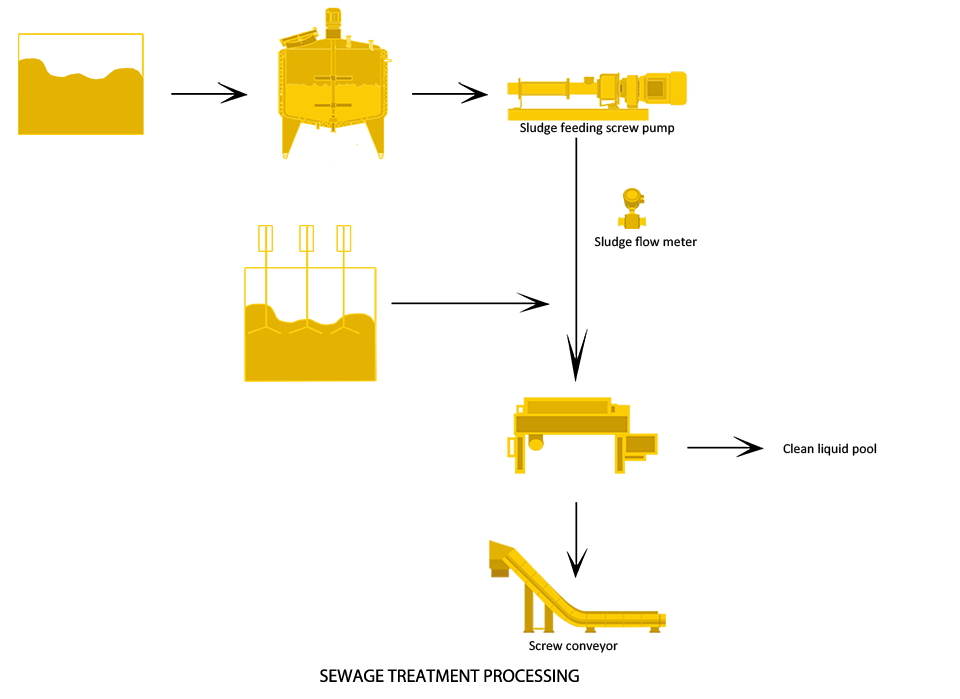

As more and more attention has been paid to environmental protection, Waste water or sludge treatment has become the most important issue of environmental protection. Wastewater treatment plants for municipal and farm applications are designed to produce a clean, safe water discharge. Complexity of the plant depends on the immediate environmental considerations and consent limits negotiated with authorities. New plants built today are more and more sophisticated, making the decanter centrifuge ideal for precise wastewater treatment. Wastewater or Sludge series decanter centrifuges from Crown Machinery provides effective concentration, dehydration during the waste water treatment process, also apply to the working water purification and reuse. For the high pH value material, highly corrosion proof material of the wetted parts is adapted.

• High separation efficiency due to perfectly coordinated components

• Quick and safe commissioning due to reduced control points

• High reliability and safety since Crown Machinery assumes the responsibility for the whole system

• Maximum convenience for our customers since there is only one contact person for the complete system

• Long life span and high availability due to our full support for the whole operating system

Specifications of our Decanter Centrifuges(Sewage Treatment)

*Some provided models exclusive with list below.

|

Model |

HDC 255 |

HDC 355 |

HDC 450 |

HDC 530 |

HDC 580 |

HDC 650 |

|

Bowl Dia. |

253 |

355 |

450 |

530 |

580 |

650 |

|

Throughput (T/H) |

1~5 |

1~20 |

3~35 |

15~65 |

20~80 |

20~110 |

|

Bowl Length (mm) |

1000 |

1460 |

1800 |

2280 |

2500 |

2800 |

|

L&D Ratio |

4.0 |

4.1 |

4 |

4.3 |

4.3 |

4.3 |

|

Bowl Speed |

4800 |

3800 |

3200 |

2600 |

2500 |

2400 |

|

Separation Factor |

3260G |

2868G |

2575G |

2006G |

2030G |

2096G |

|

Screw Differential |

5-30 Stepless Adjustable |

2-20 Stepless Adjustable |

2-25 Stepless Adjustable |

2-25 Stepless Adjustable |

2-45 Stepless Adjustable |

2-55 Stepless Adjustable |

|

Motor (kW) |

Main Motor11 |

Main Motor18.5 |

Main Motor30 |

Main Motor55 |

Main Motor75 |

Main Motor75 |

|

Noise db(A) |

≤85 |

≤85 |

≤85 |

≤85 |

≤85 |

≤85 |

|

Weight(kg) |

1500 |

2500 |

3200 |

5200 |

7000 |

8500 |

|

Dimension |

2400x750x960 |

2790×880×1300 |

3300×920×1600 |

3730×1100×1600 |

4000×1600×1400 |

4300×1900×1350 |

Typical Industry Applications

BEVERAGE / BREWING INDUSTRY

•Fruit and vegetable juices

•Wine or Beer dewatering

CHEMISTRY / BIOTECHNOLOGY

•Production of vitamins

•VC natrium

•Calcium phosphate

•Saleratus

•Heavy alkai

•Polyacrylonitrile

•Pigments

•Solvents

•Algae (food, cosmetics)

•Fermentation broths (industrial biotechnology)

CHINESE TRADITIONAL MEDICINE

•Raw Material washing

•Effective ingredient extraction

TEXTILE

•Wool degrease

•Textile dewatering

FATS / OILS / BIOFUELS

•Fish oil

•Animal fats

•Olive oil

•Avocado oil

•Palm oil

•Coconut oil

FOOD

•Starch