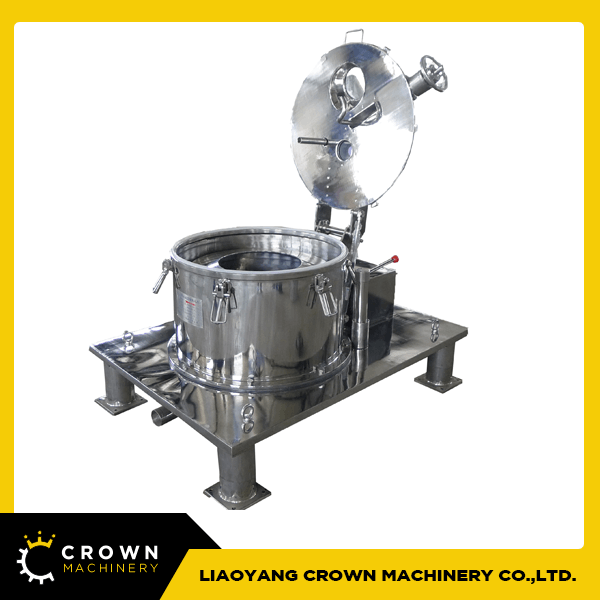

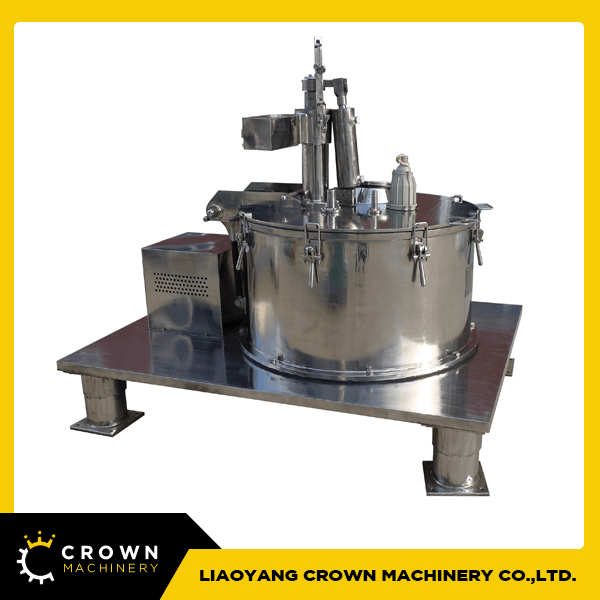

Crown Machinery™ Basket Centrifuges

Basket Centrifuges (a.k.a. Plate Centrifuges) are popular oil extracting machines widely used in the F&B Industry. This machine was invented to separate the liquid from solids through its basket-shaped filter.

It works on the principle of centrifugal force which is a high-speed revolution of solids within a metal basket and liquid is secreted out from the fast-shrinking solids revolving inside. It is also used in the Pharmaceutical and Biotechnological Industries.

The advantages of Basket Centrifuge

Large capacity

Low cost

Stable running performance

High separation efficiency

FSS Series Filter Centrifuge

In Filtering centrifuge, the solids & liquids are separated by centrifugal force using a filter media (usually a cloth) mounted over supporting mesh, which are together supported inside the rotating basket. The slurry to be filtered is fed through the feed nozzles to the basket and due to centrifugal force the liquid is forced out through the filter media while solids are retained within the filter media inside the bowl. These solids then separated or discharged by various discharging methods namely – manually, bag lifting basket, through scrapper, operated manually pneumatically/hydraulically, for which different models are available.

FCS Series Sedimentation Centrifuge

This type centrifuge operation as a simple decanter system. Feed material is dumped into the rotating basket where solids are collected in the rotating basket by accelerated sedimentation from the rotating G – force. Lighter liquid overflows the basket into the out chamber where it drains the centrifuge by gravity or flows out via a drainage pipe on the top. This centrifuge has ability to separate and capture some heavy liquid in the basket along with solids. Removal of solids must be done for each batch either manually or with an automated discharge system.

FSS/FCS series Basket Centrifuge

|

Model |

FCS(FSS) | FCS(FSS) | FCS(FSS) | FCS(FSS) | FCS(FSS) |

|

450 |

600 |

800 |

1000 |

1250 |

|

|

Bowl Diameter |

450 |

600 |

800 |

1000 |

1250 |

|

Volume |

24 |

45 |

100 |

150 |

280 |

|

Max.Loading |

30 |

100 |

142 |

200 |

400 |

|

Separation |

1008 |

700 |

1008 |

806 |

567 |

|

Bowl Speed |

2000 |

1420 |

1500 |

1200 |

900 |

|

Weight |

490 |

610 |

3000 |

4000 |

5000 |

|

Power |

2.2 |

3.0 |

7.5-11 |

11-15 |

18 |

Typical Industry Applications

BEVERAGE / BREWING INDUSTRY

•Fruit and vegetable juices

•Wine or Beer dewatering

CHEMISTRY / BIOTECHNOLOGY

•Production of vitamins

•VC natrium

•Calcium phosphate

•Saleratus

•Heavy alkai

•Polyacrylonitrile

•Pigments

•Solvents

•Algae (food, cosmetics)

•Fermentation broths (industrial biotechnology)

CHINESE TRADITIONAL MEDICINE

•Raw Material washing

•Effective ingredient extraction

TEXTILE

•Wool degrease

•Textile dewatering

FATS / OILS / BIOFUELS

•Fish oil

•Animal fats

•Olive oil

•Avocado oil

•Palm oil

•Coconut oil

FOOD

•Starch