In order to achieve maximum efficiency and profitability in dealing with these, manufacturers of tomato products need processing equipment that is versatile enough to handle a wide range of different types of products. It is also important that it is modular in construction, to make it easier to deal with constant changes in market requirements.

Hygiene issues are also increasingly important, and the quality and dryness of the processed tomato paste are crucial parameters in ensuring commercial success.

The process

A wide range of products can be obtained from tomatoes, including tomato juice, paste, diced/peeled tomatoes, strained tomato pulp, sauces and powder. For the industrial market, tomato paste is probably the most important product because it is used as the basis for a wide range of other products.

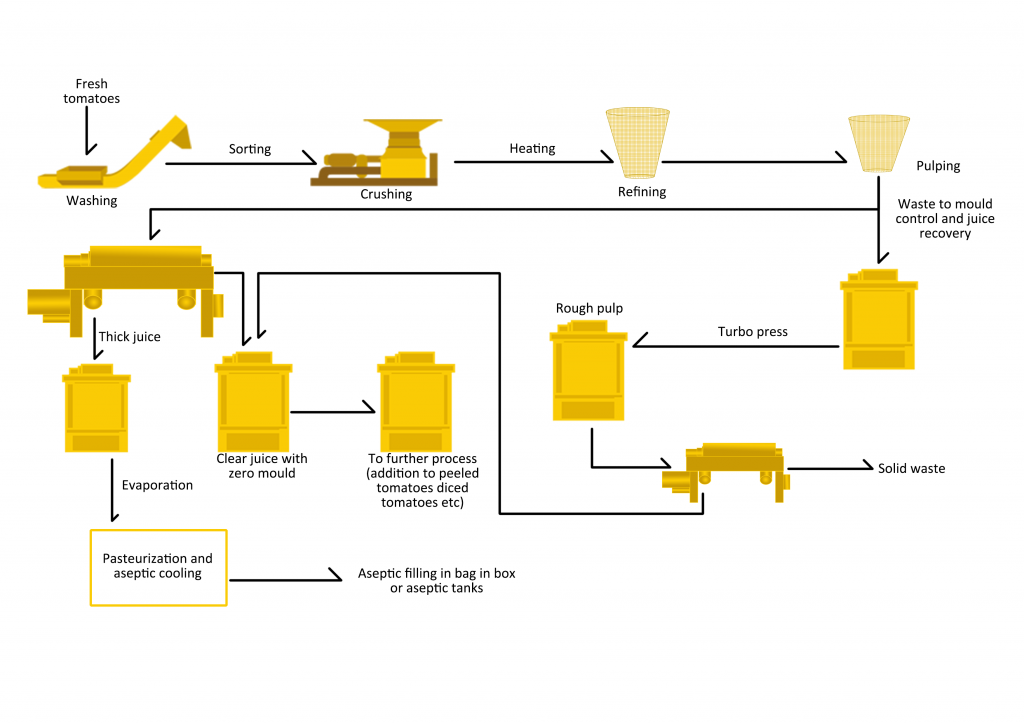

In general, the fruit is washed, sorted and pre-conditioned by crushing, peeling or cutting it to the required size. Depending on the particular requirements, the pre-conditioned fruit then undergoes heating, refining, pulping, reconditioning, evaporation, pasteurization and packing. Separation is a key part of the reconditioning stage of this process. By removing any moulds present, separating out the pulp and clarifying the juice, the manufacturer can control the colour, mould content and viscosity of the final product.

These are the key parameters that determine quality, and thus have an influence on value chain.

Centrifuge in tomato processing

Tomato processing is seasonal, with a limited period of only 60–100 days per year. There are a very large number of different varieties of tomatoes, and the quality also depends heavily on climatic conditions and weather.

For all manufacturers, the main requirement is therefore to have an efficient, reliable and versatile processing plant that is in continuous operation. Manufacturers are constantly on the lookout for any possible means to improve both quality and yield.

Separation plays a major role in their ability to do this, and Foodec decanter centrifuges are the ideal solution for this task.

Benefit from Foodec decanter centrifuges in your tomato processing

Foodec decanter centrifuges feature a series of built-in advantages including

- better solids transportation that enables you to boost solids handling capacity by up to 25%

compared with all other designs currently available – at no additional cost

- special sanitary design that enables you to match stringentFDA, 3A and USDA standards. The Foodec design also focuses on ease of cleaning

- an advanced drive system that enables you to operate at any given capacity with significantly lower power consumption than other current designs

Tomato Sample Processing Line