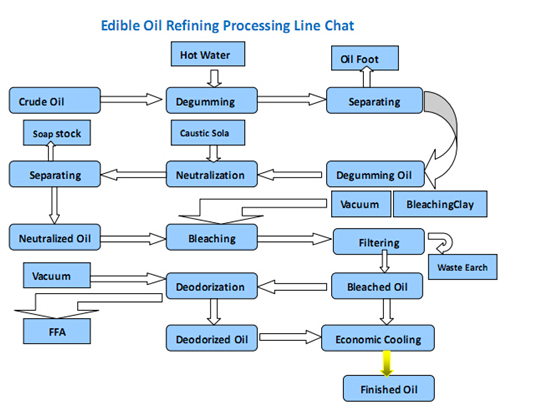

The Vegetable Oil Processing Industry involves the extraction and processing of oils from vegetable sources which include a variety of greens, fruits, seeds, and nuts. The preparation of raw materials includes husking, cleaning, crushing, and conditioning. The extraction processes are generally mechanical (boiling for fruits, pressing for seeds/nuts) and involves the use of solvent such as hexane. After boiling, the liquid oil is skimmed; after pressing, the oil is filtered; and after solvent extraction, the crude oil is separated and the solvent is evaporated and recovered. The residue is conditioned (or dried) and are reprocessed to yield by-products such as animal feed. Crude oil refining includes degumming, neutralization, bleaching, deodorization, and even further refining.

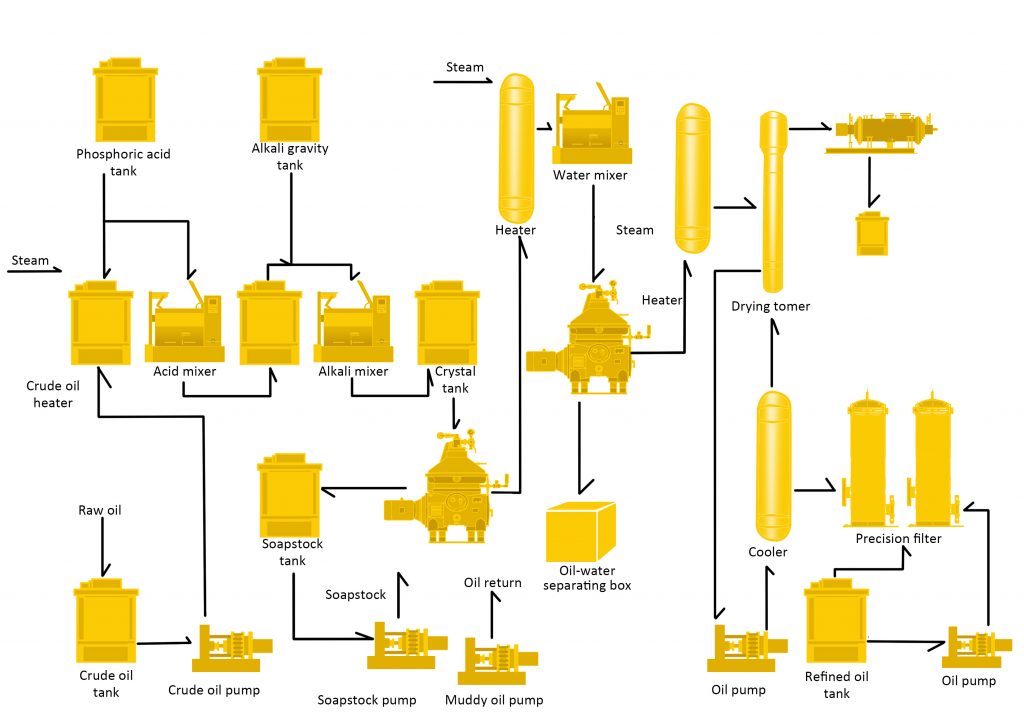

Crown Machinery designs and manufactures a “customized” solution which is tailored to meet the requirements of any specific application. Every client is able to find the best solution in economic and technological terms for any specific production task. The centrifuge is always found at the heart of installation. Of course, besides the mechanical separation facility, we also supply all other components and systems necessary for an efficient and reliable production line for clients.

Vegetable Oil Sample Processing Line