Palm oil is a very productive crop. It offers a far greater yield at a lower cost of production than other vegetable oils. Global production of and demand for palm oil is increasing rapidly. Global production of palm oil has doubled over the last decade. Worldwide demand for palm oil is expected to double again by year 2050 to 240 million tones.

To help improve production efficiency and optimize profits, Crown Machinery has developed customized solutions for flexible process management, which minimize water and energy consumption. In addition to providing advanced individual machines, we can supply entire process lines, or even design and implement complete, customized installations. Crown Machinery centrifugal separation technology, concentration equipment guarantee maximum yields at any scale of production.

Oil recovery and Oil refining: Innovative Process Technology

Crown Machinery offers process technology for the recovery and refining of palm oil, as well as oil refining for press oil clarification, degumming, neutralization, dewaxing, fractionation and soapstock splitting. Our technologies are also used for the production of high-quality biodiesel.

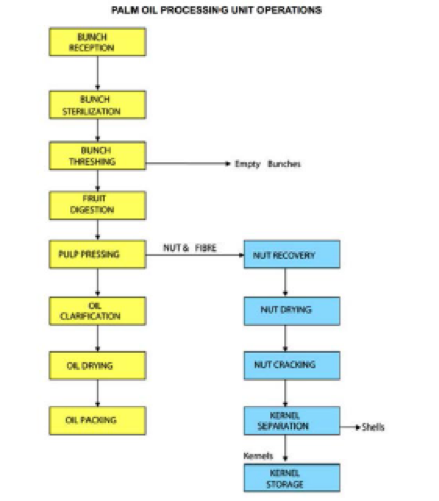

Process of Palm Oil and Palm Kernel Oil production

Red Oil Extraction

Digested fruit is continuously conveyed through the cage towards an outlet restricted by a cone, which creates the centrifugal force to separate the oil and the water from the mixture. Oil-bearing cells that are not ruptured in the digester will remain unopened if or centrifugal extraction system is employed. It can effectively break open the unopened oil cells and release more oil. These centrifuge act as an additional digester and are efficient in oil extraction.

Sample Palm Oil Processing Crown Machinery Centrifuge

Oil Purification and Recovery

The main point of clarification is to separate the oil from its entrained impurities. The fluid coming out of the press is a mixture of palm oil, water, cell debris, fibrous material and ‘non-oily solids’. Because of the non-oily solids the mixture is very viscous. Hot water is therefore added to dilute it.

To prevent increasing FFA through autocatalytic hydrolysis of the oil, the moisture content of the oil must be reduced to 0.15 to 0.25 percent. Centrifuge can help you solve that problem.

Sample Palm Oil Processing Crown Machinery Centrifuge