It is well known that from time to time mines are confronted with the issue of very turbid water flowing from their tailings thickener. The clarity of this water from the thickener can deteriorate to an unacceptable level resulting in the wash plant shutting down and production ceasing. Substantial losses in productivity and revenue can result.

Given increasing environmental concerns and greater emphasis on water conservation and recycling the use of mechanical separation technology with centrifuges has become increasingly accepted in mining and quarrying where large quantities of water are used for a variety of processes. These processes generate a high content of fine particles that must be separated.

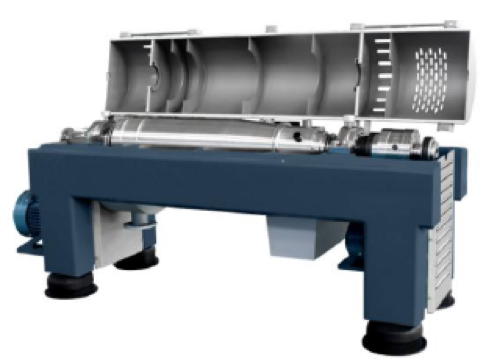

For dewatering and thickening sewage slurry, it is necessary for special properties of the bowl, gear unit and control system to be guaranteed. This is the only way to achieve maximum dewatering and thickening of the sewage slurry. Our centrifuge series is the generation of environmental centrifuges which is characterized by familiar quality and reliability as well as an optimum performance ratio.

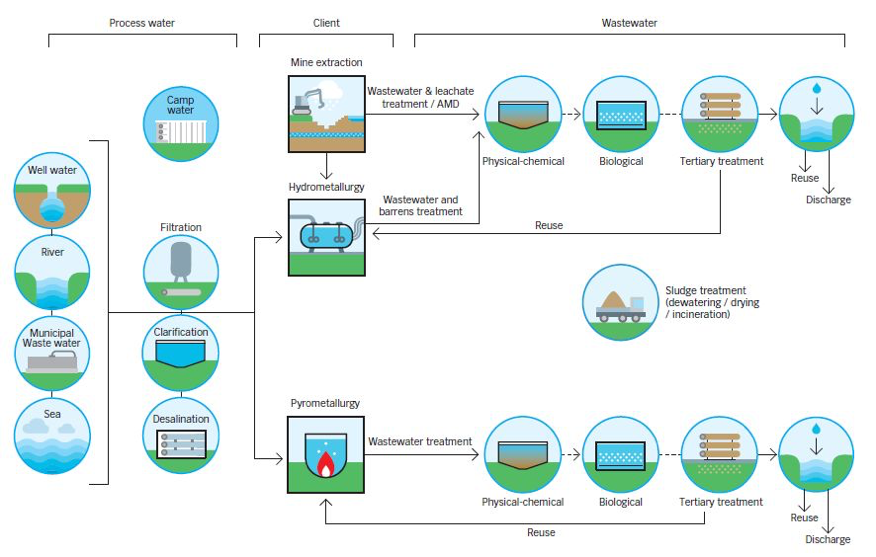

Mining Waste Water Treatment Sample Processing Line

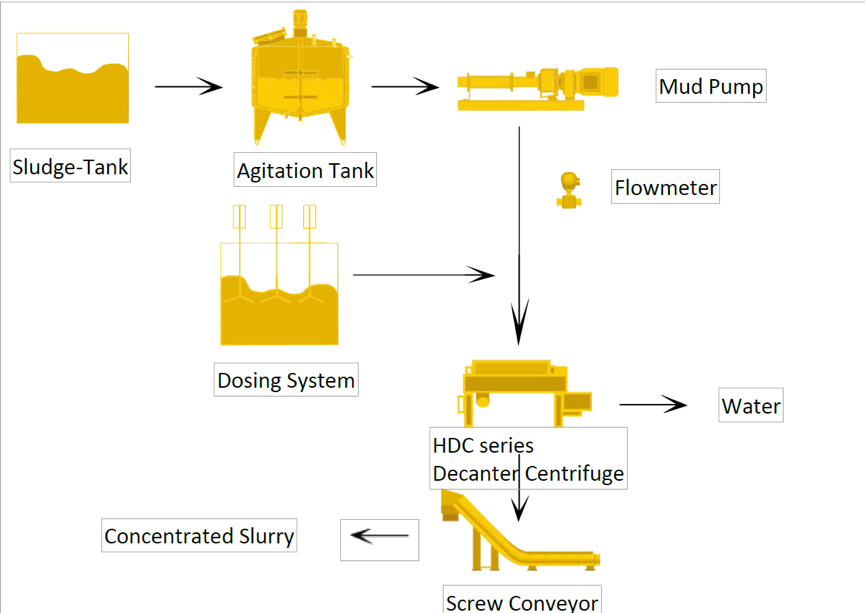

Mining Waste Water Processing Sample Crown Machinery Centrifuge

Mining Waste Water Processing Sample Crown Machinery Centrifuge Setup