Dairy products can become heavily contaminated by bacteria, somatic cells and non-milk constituents. This makes it all the more important to remove bacteria from the raw and vat milk as well as the whey efficiently, a job that is reliably performed by the bacteria-removing from centrifuges. The application spectrum ranges from the one-stage and two-stage and special bacterial clarification of drinking milk through variable bacterial clarification of cheese-making milk right up to treatment of the whey concentrate.

The bacteria-removing centrifuge separates in particular spore formers such as Bacillus cereus, heat-resistant up to 128 °C and cold-tolerant at the same time, which negatively impact the shelf life of the drinking milk due to sweet coagulation. A large number of cheese defects can likewise be prevented effectively through the application of bacteria-removing centrifuges.

The use of nitrate is also largely superfluous or can be dispensed with completely. Due to the higher specific gravity of the spores compared to the raw milk and skim milk, they can be removed from the milk extremely efficiently with the aid of bacteria-removing centrifuges.

The design of the centrifuge – the feed, disk stack and centripetal pump in particular – is configured optimally for this task. Additionally, every bacteria-removing centrifuge is equipped with a so-called recirculation system. Up to 3% of the feed volume is tapped off as carrier liquid and recycled back into the feed. In this way, the spores can be reduced by up to 99%.

Sample Crown Machinery Centrifuge for Milk and When Processing

Depending on the type of whey and the desired consistency, the dry mass content can be variably adjusted with the decanter. The dewatered end-product can be further processed in different ways. With consistent hygienic processing, it can be used as food.

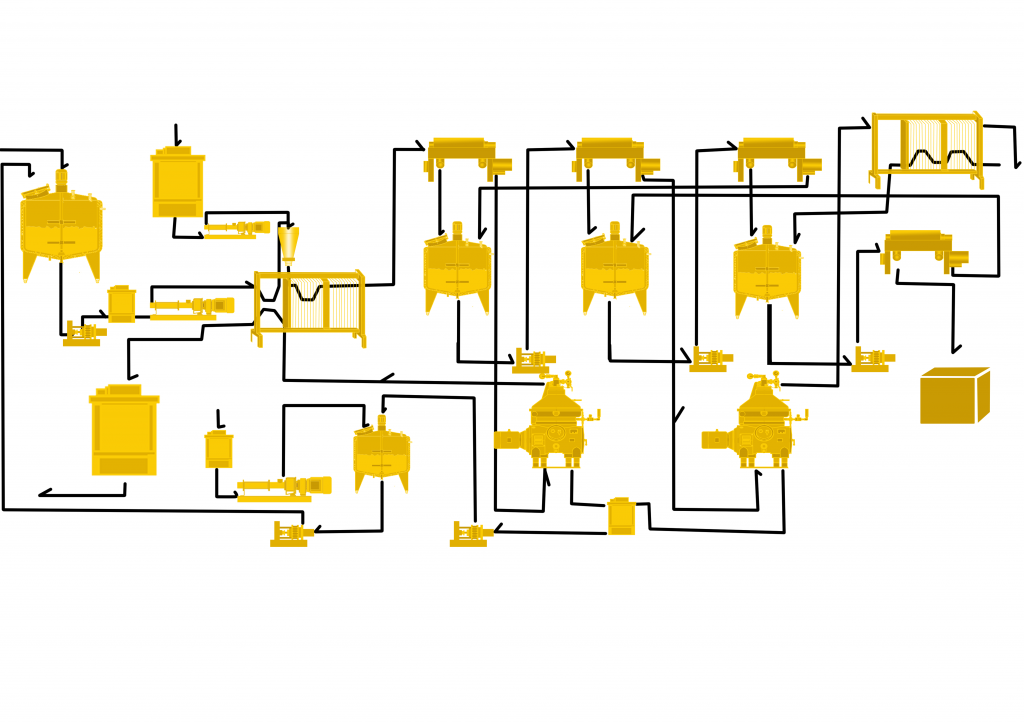

Sample Whey Processing Line