Slop oils are usually characterized by relatively high oil content (in the order of 50-90% by volume). If collected near to the source, the solids content is usually rather low (in the order of 15% by volume). Often slop oils are collected in open lagoons, which lead to different product properties such as an increase in viscosity and a higher solids content due to the evaporation of lighter hydrocarbons plus sediment carry-over when the sludge is dredged from the lagoon. Another result of the storage in lagoons is those sludges require thorough mixing in order to revert the negative effects of stratification, usually after removal of coarse solids. Slop oils very often contain a fourth emulsified phase. For the sake of improved solids removal and optimal oil-water separation, those emulsions are normally destroyed by dosing of de-emulsifier before the feed product is processed.

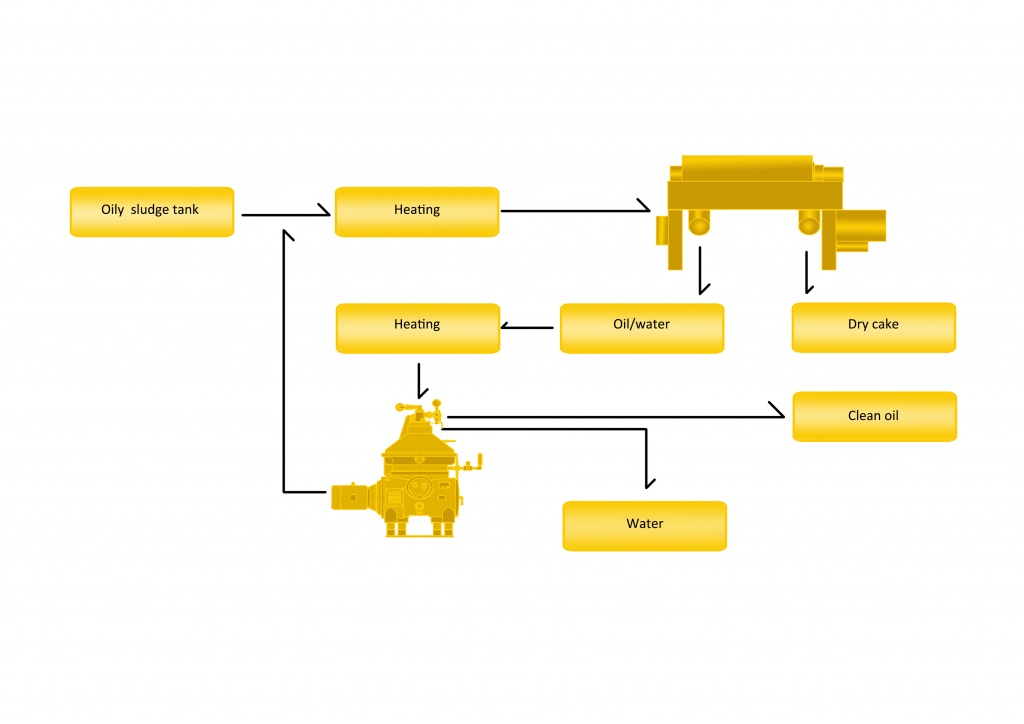

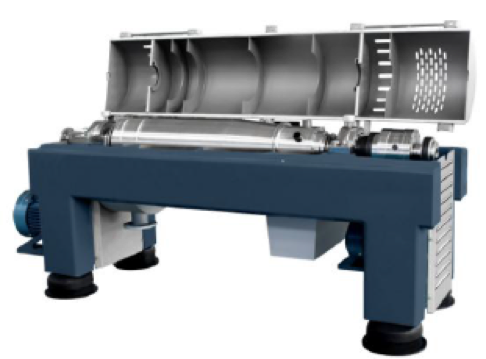

Waste oil, water, and solids separation in one high performance 3-phase decanter centrifuge. Oil quality produced in such a system is usually good enough for return to the crude oil side of the refinery.

Typical 3-phase decanter performance:

Oil phase:

1-3% water

Below 1,000 ppm solids

Water phase:

1-3% oil

1,000-3,000 mg/L solids

Solids phase:

20-50% dry solids

Hydrocarbon content depending on product

Sample Gutter Oil Centrifuge