The separation of dyes, paints, and ink is a liquid phase procedure containing colored particles. What appears to be uncomplicated at first sight actually proves to be a challenge upon closer inspection. This is because particles with precisely the right size must be used to achieve the desired colour as a protective function. The solution in this case undergoes centrifugal separating technology with specific classifying centrifuges.

In classifying centrifuges, the separating conditions are adjusted in such a way that only the desired particle size class is retained in the end-product. The centrifuge removes all other particles efficiently.

The very small particles of a few micrometers required in dyes, paints, and ink mean that high speed and large clarification areas are frequently required. To guarantee maximum quality, the discharge system can be controlled with solvents. No operating water comes in contact with the end-product. If organic solvents are used in production, it is necessary to use explosives protected centrifuges incorporated with special fittings and materials.

In addition, Crown Machinery specially developed an Ink tubular separator to save the membrane filtering costs.

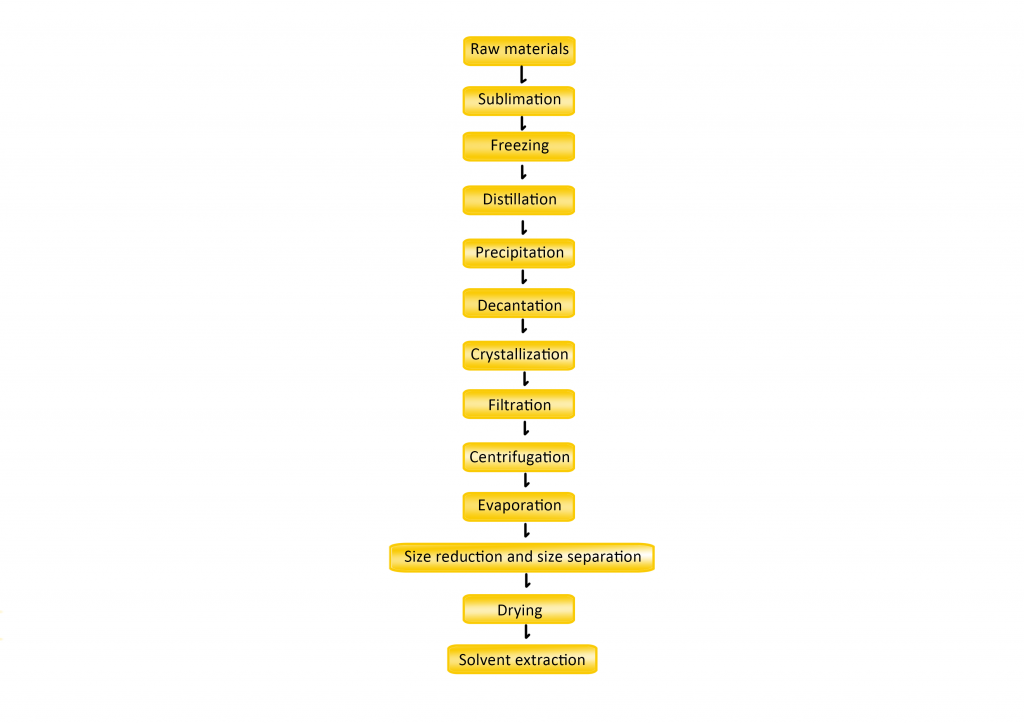

Dye,Paint,Ink Sample Processing Line