Differential and Overflow Ports:

To maintain an appropriate speed difference between the bowl and screw conveyor, a differential is used, along with an overflow baffle that regulates the overflow port diameter. Generally, in a horizontal screw centrifuge, the larger the overflow port diameter, the greater the residual dryness obtained, but the slag contains more liquid. Additionally, the equipment’s bowl utilizes a cylindrical and conical combination structure to provide favorable conditions for solid-liquid separation.

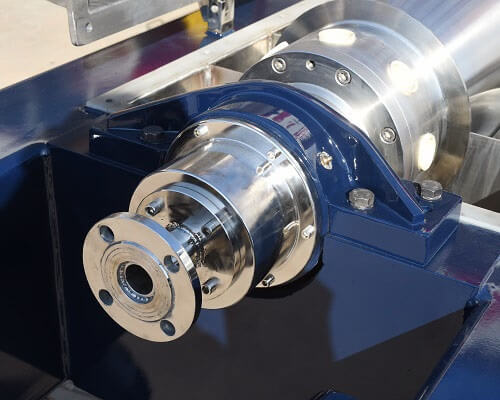

Special Treatment for Bowl:

When designing the horizontal screw centrifuge’s bowl body, an annular flange is added to its surface to prevent clarified liquid from entering the sludge discharge chamber. To achieve the desired separation effect, users can adjust the bowl’s rotational speed by controlling the motor speed. Before welding begins, all personnel must wear work clothes and gloves. During the welding process, it is forbidden to touch the area near the beveling machine’s two ends. Additionally, hitting the surface and bevel of the horizontal screw centrifuge with iron tools is prohibited.

Welding Treatment:

After cleaning the welding workpiece group, welding should be carried out immediately. It is also necessary to properly control the concentration of argon and helium gas to avoid affecting the welding effect. Moreover, after welding the horizontal screw centrifuge, the bevel and the area within 25 millimeters around it must undergo rigorous mechanical cleaning and degreasing. During the entire welding process, corresponding protective measures must be taken to avoid contaminating the bevel.

Check the link below: Decanter-centrifuge