Municipal sewage treatment plants are designed to produce a clean, safe water discharge within the required limits. The complexity of the plant will depend on the immediate environmental considerations and the consent limits negotiated with the authorities. New plants built today are becoming more and more sophisticated and decanter centrifuges are extensively used for liquid-solid separation, sludge dewatering, and sludge thickening applications.

For the purposes of this overview on Decanter Centrifuge applications, we will consider only the basics. There are basically (2) two decanter centrifuge applications in it:

1.The first is to feed to the decanter centrifuge liquid slurry (around 1 – 3 % dws.) and thicken it to approximately 8% dws, often prior to feeding the thickened material to a biological digester.

2.The second is to feed the decanter with similar slurry and dewater the solids to a relatively dry stackable cake of leach free solids prior to transportation or disposal. In the second case the solids can come from the primary clarifier or the secondary clarifier after biological treatment.

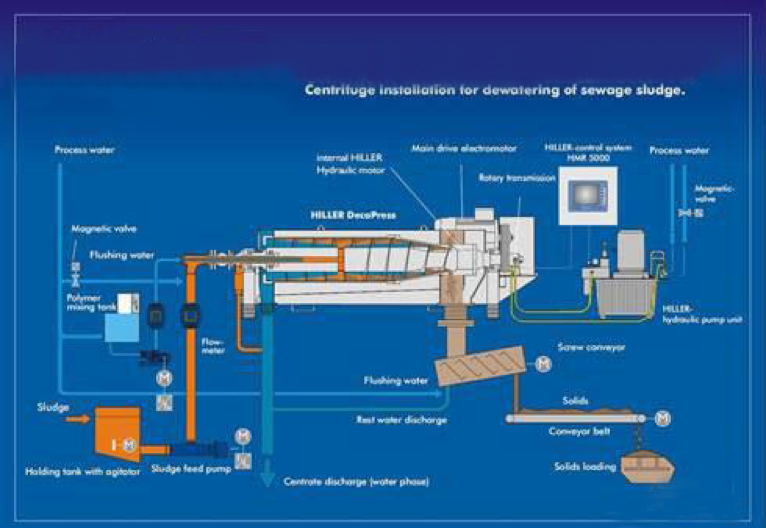

A simplified and typical flow-chart for wastewater applications is shown below although not all process steps are present, particularly for industrial wastewater.

Sludge discharge consistency can be regulated to suit the disposal requirements. Slurry for land application should be thickened to reduce the volume of water but still needs to be fluid enough to be easily spread or evenly pumped for land application. Digester feed slurry can often be thicker but typically requires a pump-able sludge. When the discharged sludge will be disposed of via landfill, dewatering the feed slurry to a stackable consistency reduces weight, volume and disposal costs.

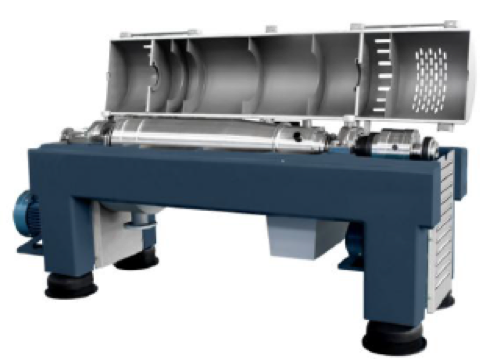

Sample Crown Machinery Centrifuge for Municipal Waste Water Treatment

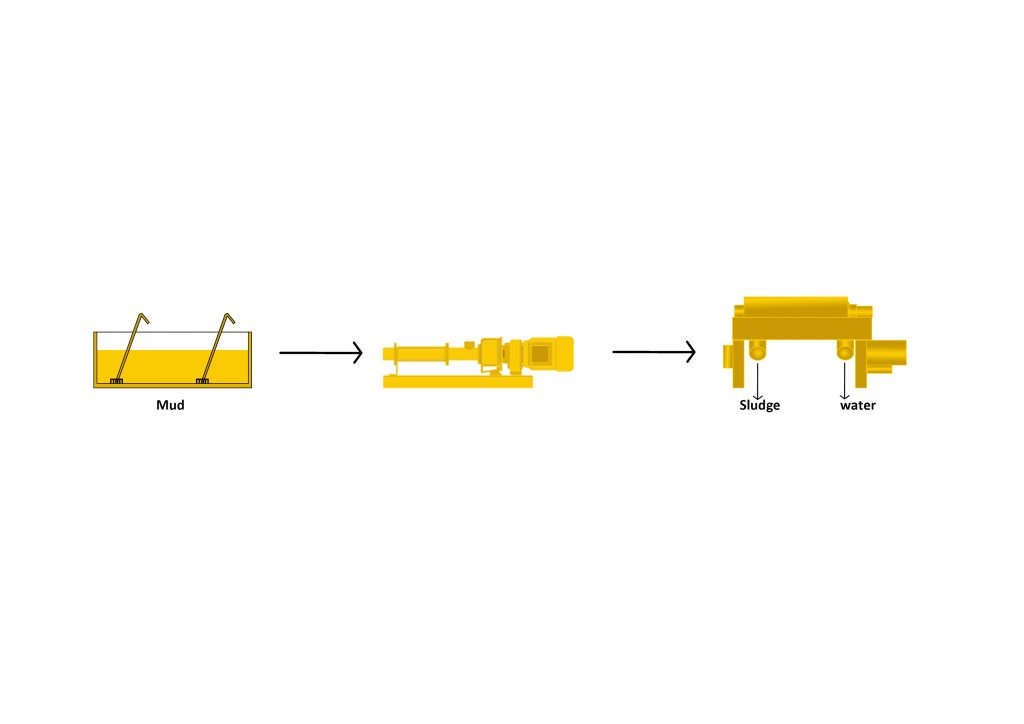

Sample Municipal Waste Water Treatment Processing Line