Algae are the precursors for many different branches of industry whether in the cosmetics industry, pharmaceuticals, manufacture of biofuels or foodstuffs production.

Algae are very diverse and easily found everywhere on the planet. Algae can be grown using water resources such as brackish, sea, and waste water unsuitable for cultivating agricultural crops. They can even help in waste water treatment and purification, while benefiting from using the nutrients present.

In fact, algae can theoretically produce up to 300 times more oil per acre than conventional crops, such as rapeseed, palms or soybeans, and have a short harvesting cycle -one to ten days. Algae processing face many challenges, from processing capacity limitations to production costs. To address those problems, Crown Machinery is joining in to help to fins out separation technology solutions.

Harvesting is defined as the separation of algae from a growing medium. Techniques for harvesting algae include settling or flotation, centrifugation, and filtration. In any case, it is the harvesting method which is crucial to the efficiency of the entire process in terms of investments as well as operation costs. In this process, commonly used machines is a continuous-flow centrifuge. It is efficient and collects both algae and other particles. However, it is more commonly used for production of value-added products from algae. Centrifuge can achieve high cake dryness in the separation and low energy demand during the process.

Our excellent product disc stack centrifuge and decanter centrifuge can greatly shorten production cycle by accelerating clarifying time and reduce labor cast, and guarantee the purity of final products at the same time.

BREAKTHROUGHS IN OIL EXTRACTION FROM ALGAE

Single-Step oil extraction process is simpler and more efficient than current systems, without requiring chemicals or significant capital expenditure for many machines. Only one appropriate disc centrifuge or decanter centrifuge can speed up the whole process.

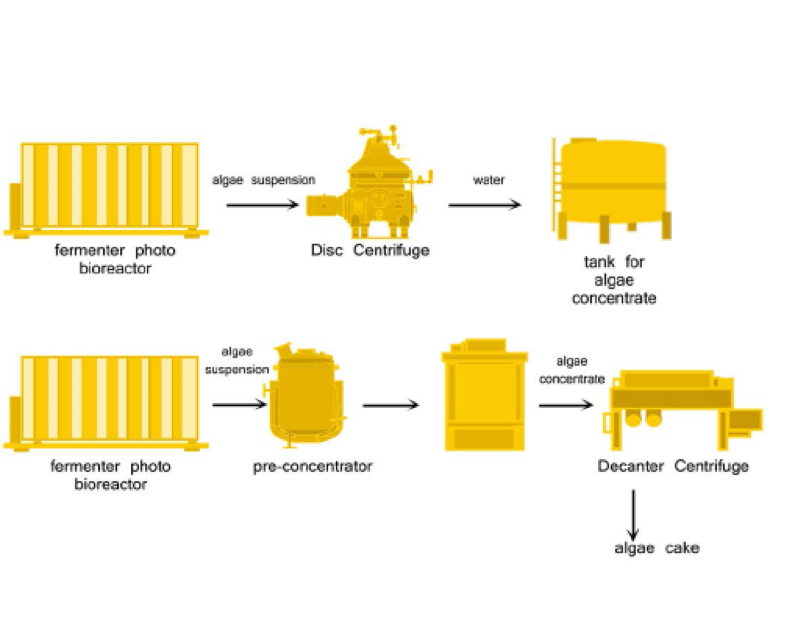

microalgae sample processing line

The Single-Step Process harvests, concentrates and extracts oil from algae, and separates

oil, water and biomass in one step. No initial dewatering is required, and separates the oil, water and biomass in less than an hour.

Algae : A Start-point to Change

With the rapid development of economics, the whole world is facing strict resources shortage, like, food, energy, therefore, novel solutions will be required. Algae, as a renewable and sustainable resource, stands out.

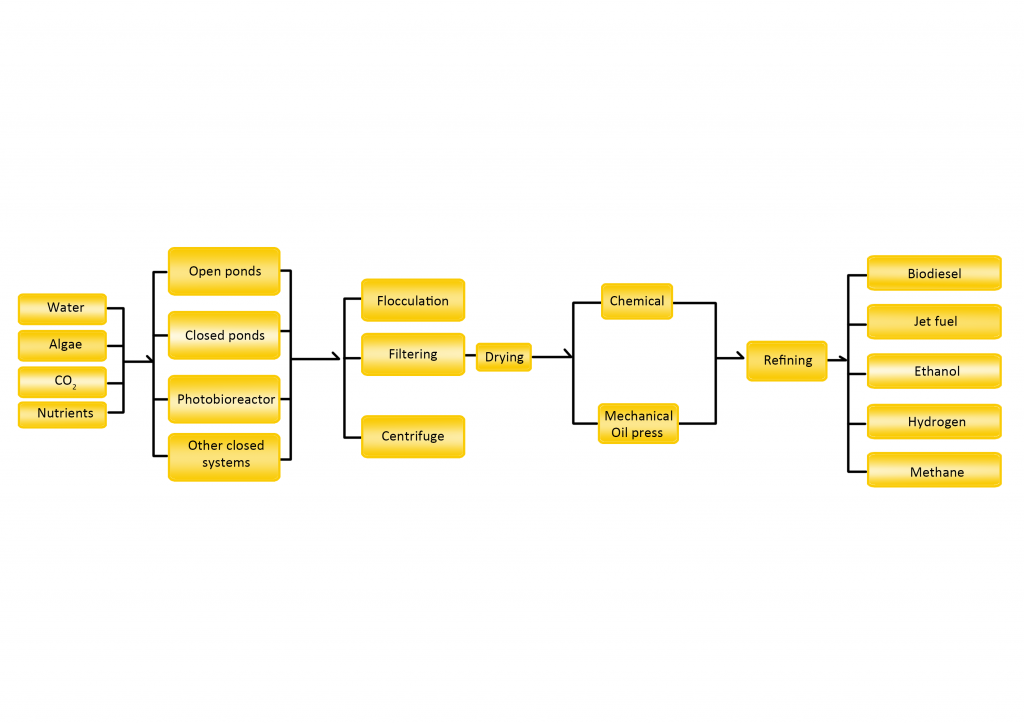

Biofuels

Biodiesel is the most commonly discussed energy output from algae. Due to their growth rate and yields, algae can theoretically produce 10 to 100 times more oil than other “energy” crops, but it is not the only one. There are all the way from gasoline to hydrogen to LPG. The following is the list of fuels that can be obtained from algae.

Nutraceuticals

Algae are important foods in many nations, especially in Asia and America. They provide many vitamins including: A, B1, B2, B6, niacin, and C, and are rich in iodine, potassium, iron, magnesium, and calcium. In addition, commercially cultivated micro-algae, are marketed as nutritional supplements, for Astaxanthin, Omega 3 Fatty Acids, Beta Carotene, CoenzymeQ10, Spirulina, Chlorella.

Pharmaceuticals & Health Related Products

Use of algae, especially the cyanobacteria (blue-green algae), for antibiotics and pharmacologically active compounds has received ever increasing interest. There are a range of pharmaceutical products derived from algae. Some of them include: antimicrobials, antivirals & anti-fungals, neuro-protective products, therapeutic proteins and drugs.

Cosmetics

In cosmetics, algae act as thickening agents, water-binding agents, and antioxidants. Algae are used in cosmetics in the forms such as algal flakes, algal oil, algal powder and algal flour. Cosmetics that could be produced from algae include soaps, clay mask, beauty serum, beauty oil, oil/salt scrub, algal whole cell shampoo and conditioner, algae anti-ageing creams and so on.

Animal & Fish Feed

The production of low-cost fish and animal feed from algae can provide a natural food source for fish and farm animals

Pollution Control

Algae are currently used in many wastewater treatment facilities, reducing the need for more dangerous chemicals. Algae can be used to capture the runoff fertilizers that enter lakes and streams from nearby farms. Algae are used by some power plants to reduce CO2 emissions.

Algae Centrifuge Machine Standard Design

The machine has a main frame that consist a horizontal drive shaft with clutch and brake, worm gear, lubricating oil bath and vertical bowl spindle in the lower position.

The bowl is mounted on top of the spindle, fixed by the upper parts, the gasket, the collecting parts, and frame hood. The material feed into the bowl, by the effects of centrifugal force the liquid phase pumped out of machine through outlet pipe, meanwhile the solid phase adhere on the bowl wall, then were discharged automatically by operation water. The electric motor is of the variable frequency drive type or of controlled-torque type. All parts in contact with material are made of stainless steel.

Benefit of Crown Disc

centrifuge in Algae Harvest Disc stack centrifuges are suitable for use in the harvesting stage to separate the algae cells from the liquid growth media. It works at a high rotation speed generating more powerful centrifugal force which means that it’s efficient to separate ultra fine solids particles from liquids and separate two different liquids by density. Automatically discharging can greatly reduce labor cost.

Micro Algae Recovery Sample Flow Chart